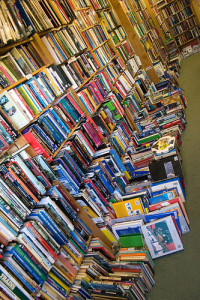

Stacked a Little Bit Too High… Image credit: Krypto

The recent earthquake and tsunami in Japan got us to thinking. First of all, if you haven’t hugged your structural engineer lately, you should probably do that now. While their jobs aren’t the most glamorous, their work in Japan, along with some pretty stringent building codes, clearly saved many lives. And since Cardphile’s holiday greeting card design and printing facility in Portland shares a similar earthquake risk zone, we took some notes and decided it was time to take a good look at our warehouse.

Here’s what we found:

- Fire extinguishers? Check

- First aid and medical kits? Check

- 100% Windpower for all production? Check

- Lunchroom fridge cleaned regularly? um… Action Item ;(

- Stock shelves all strapped down and secured? …Oops!

So we called up one of our local engineering friends and arranged for a review.

Turns out, while most of our warehouse was in pretty good shape, there were definitely a few places that needed some attention. Although it was well within code, he saw a few things stacked just a little bit too high….

Other items he suggested:

- Additional rack anchors. This was suggested because the thickness of the base plates and concrete floor are adequate to support it. Again it was going beyond code for our area, but cheap insurance. Good Idea!

- Add “drag struts” to the top levels of shelving. Another inexpensive, but highly effective technique to reduce potential damage and injuries.

- Other suggestions were to add diagonal bracing or rigid frames. However, since this was going to be quite a bit more expensive, and exceed the structural integrity of the building shell, we decided it would be more logical to just restrict the storage height.

- Identify safe zones for everyone to go which have few overhead or large items. Even items like overhead lighting, ceiling tiles, bookshelves, filing cabinets and yes, even our lunch room fridge can become a hazard during a significant earthquake.

- Define a central place for everyone to gather after an earthquake so all can quickly be accounted for. Keep in mind that it should also be free of overhead obstacles.

We were surprised to discover that it doesn’t have to be expensive: a few simple changes can help you protect staff and make your work environment a lot safer.

We’re as likely as anyone else on the Pacific West Coast to avoid preparing for “the big one,” but seeing how our Japanese neighbors benefited from their rigorous building codes gave us pause for thought.

In much better shape now, we’ll have lots to talk about at the next office meeting.

Make sure your workplace is safe too. You can find a licensed engineer by checking in with the American Society of Civil Engineers.

The American Institute of Architects is also a great place to find an architect to help you with a review of your own workspace. Or, you could even give us a call – chances are pretty good that we’ll know a registered architect in your area!

(Oh, and here’s the engineering holiday card design our engineering friend picked out to send to his clients this Thanksgiving!)

Let us know if we missed anything – we’d love to hear your suggestions for how we can all make our offices safer places to work!